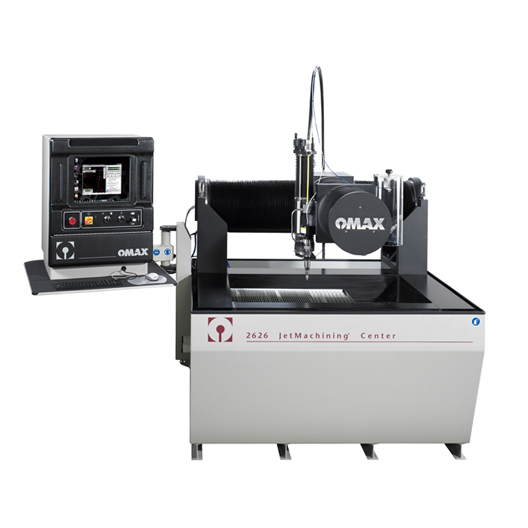

OMAX 2652

The original OMAX JetMachining® Center, the 2652 is a popular fixture in machine shops and fabrication facilities. The proven OMAX technology leads to efficient production through fast and accurate cutting of complex parts out of most materials. With the simple yet powerful Intelli-MAX® Software Suite and innovative optional accessories such as the Tilt-A-Jet®, the 2652 can quickly switch from near net blank shape cutting to high precision machining.

For further information and orders, please contact 01257 248480.

Features

- Fastest cutting speeds and best precision compared to any abrasivejet in the industry and is backed by our exclusive Intelli- MAX® Software with real world cutting data

- Programmable Motorized Z-Axis with a precision OMAX MAXJET®5i Nozzle boosts productivity and process efficiency

- Optional Tilt-A-Jet taper eliminating abrasivejet cutting head

- Precision X-Y Axis rigidly mounted to the cutting table

- Pre-loaded linear bearings and precision ball screws

- Easy operator access to the work area

- Low maintenance, high reliability scissor-style hard plumbing

- Drive system sealed against water, dirt, and grit

- High efficiency Generation 4 EnduroMAX® pump systems available in 30, 40, or 50 hp with operating efficiencies up to 85%

- Robust and accurate design for tight tolerance cutting and reliable operation

- Rapid Water Level Control for quiet submerged cutting

- Optional Variable Speed Solids Removal System (VS-SRS) designed for industrial use increases uptime through automated solids removal

- Factory tested as a complete system before shipping

Benefits

- Machines a wide range of materials and thicknesses, from metals and composites to glass and plastics

- Designed and manufactured at the OMAX factory in Kent, Washington, USA

- Does not create heat-affected zones or mechanical stresses

- No tool changes & minimal fixturing dramatically reduce setup

- Uses substantially less cooling water than inefficient hydraulic intensifier pumps

- Small, efficient footprint for minimal floor space utilisation

- Lowest electrical consumption compared to other pump technology

- Leaves behind a satin-smooth edge, reducing secondary operations

- No noxious fumes, liquid or oils used in, or caused by, the machining process

- EnduroMAX pump technology delivers the highest nozzle horsepower in the industry for faster and more efficient cutting

- Completes most work below 80 dBA

- Environmentally “green” system uses only natural garnet abrasive and water in the cutting process

- Highly robust and reliable pump design capable of over 1000 hours between maintenance

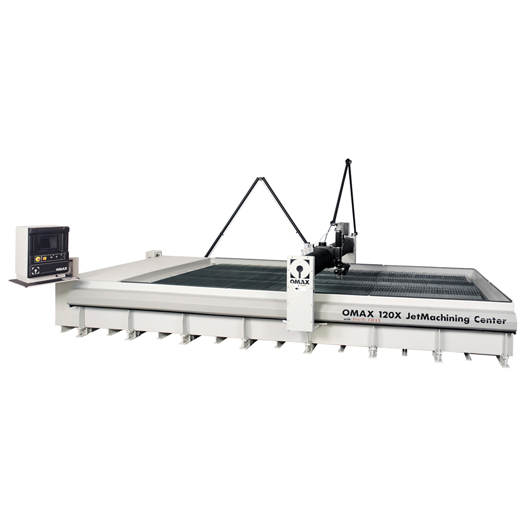

Other OMAX Machines

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)

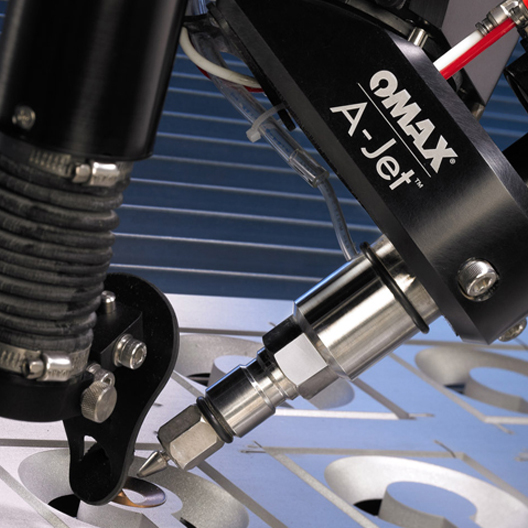

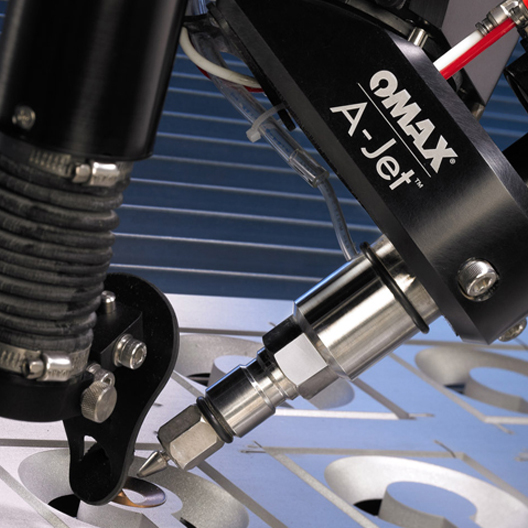

A-Jet

The patent-pending A-Jet® is a complete software-controlled, multi-axis accessory that features the flexibility to automatically compensate for taper, as well as cut severe angles up to 60° off vertical.

The A-Jet cuts countersunk holes and precision shapes with beveled edges at angles specified by the user. The accessory supplies additional axes of motion, allowing the operator to fabricate and shape metal edges for weld preparation.

The dynamic A-Jet is capable of a high level of positioning accuracy, resulting in parts that need no secondary finishing.

For further information and orders, please contact 01257 248480.

Description

Features

- High resolution magnetic encoder senses change in material height

- Automatically maintains nozzle standoff throughout the cutting process

- All electrical cabling is shielded from the abrasive waterjet environment

- Designed with robust packaging, O-ring seals, and splash guards

- All A-Jet accessories contain mounting features to add on a Terrain Follower device

- Quick and easy removal/attachment of the Terrain Follower accessory

Benefits

- Adjusts automatically to uneven surfaces, reduces need for additional programming

- Meet required tolerances and deliver competitively priced, accurate parts cut from economical, non-precision material

- Simple setup and operation

- No special programming required

- Auto standoff

- Designed specifically to operate in an abrasive waterjet environment

- Completely retrofittable to all existing A-Jet accessories

- Designed with the experience of the proven original Terrain Follower concept, which has over 200 active units in the field

- Quick and easy removal of the Terrain Follower accessory when you want extra clearance for specific jobs

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)

A-Jet

Description

Features

- High resolution magnetic encoder senses change in material height

- Automatically maintains nozzle standoff throughout the cutting process

- All electrical cabling is shielded from the abrasive waterjet environment

- Designed with robust packaging, O-ring seals, and splash guards

- All A-Jet accessories contain mounting features to add on a Terrain Follower device

- Quick and easy removal/attachment of the Terrain Follower accessory

Benefits

- Adjusts automatically to uneven surfaces, reduces need for additional programming

- Meet required tolerances and deliver competitively priced, accurate parts cut from economical, non-precision material

- Simple setup and operation

- No special programming required

- Auto standoff

- Designed specifically to operate in an abrasive waterjet environment

- Completely retrofittable to all existing A-Jet accessories

- Designed with the experience of the proven original Terrain Follower concept, which has over 200 active units in the field

- Quick and easy removal of the Terrain Follower accessory when you want extra clearance for specific jobs

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)