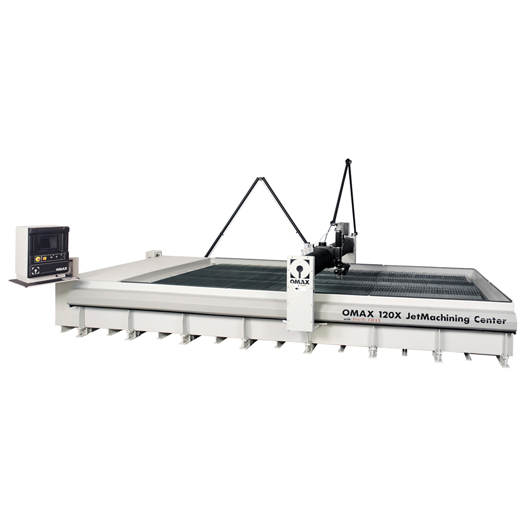

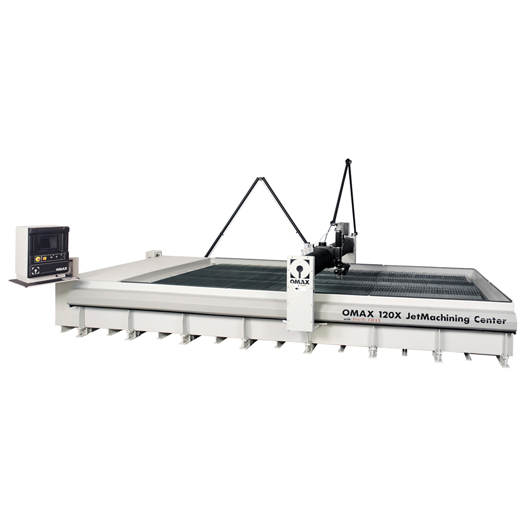

OMAX 160X Series

Abrasive waterjet machining takes on a new dimension with the OMAX® 160X JetMachining® Center. The newly developed modular 160X Series ensures that, when it comes to cutting area and performance, you get more of both.

The modular design tailors the 160X to your specific space requirements, while the exceptional drive system maximises performance: Intelli-TRAX® drive technology, an innovative system designed for the abrasive waterjet environment, is durable, reliable, and precise.

Features such as EnduroMAX® technology and Intelli-MAX® software, along with optional accessories such as the multi-axis A-Jet® and the DualBRIDGE system, all are designed to deliver lower operating costs and increased profits with the 160X JetMachining Center.

For further information and orders, please contact 01257 248480.

Description

Features & Benefits

- Fastest cutting speeds and best precision compared to any abrasivejet in the industry

- Backed by our exclusive Intelli-MAX Software with real world cutting data

- Programmable Motorized Z-Axis with a precision OMAX MAXJET®5i Nozzle Assembly boosts cutting productivity and process efficiency

- Increase machining capacity with optional DualBRIDGE system

- Low maintenance, high reliability scissor-style hard plumbing

- Drive system sealed against water, dirt, and grit

- High efficiency EnduroMAX pump systems available up to 100 hp with operating efficiencies up to 85%

- Rapid Water Level Control for quiet and clean submerged cutting

- Bulk Abrasive Feed Assembly transports garnet from the assembly’s large hopper into the Zero Downtime Hopper located at the Motorized Z-Axis

- Factory-tested for quality and precision

- Does not create heat-affected zones or mechanical stresses

- Optional 5th Generation 100 hp pump with EnduroMAX technology delivers exeptional power and the smoothest jet stream

- Machines a wide range of materials and thicknesses, from metals to glass to composites

- No additional water required for pump cooling

- Efficient footprint for optimum floorspace utilisation

- Leaves behind a satin-smooth edge, reducing secondary operations

- No noxious gases, liquid and oils used in, or caused by, the machining process

- EnduroMAX pump technology delivers the highest Jet Power in the industry for faster and more efficient cutting

- Completes most work below 80 dBA

- Environmentally “green” system with quiet and clean operation with low electrical consumption

- High reliability pump design capable of over 1,000 hours between maintenance intervals

- No tool changes and minimal fixturing reduces setup by 50% or more

Other OMAX Machines

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)

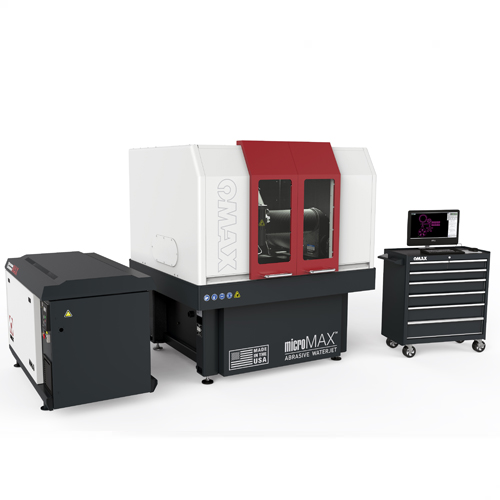

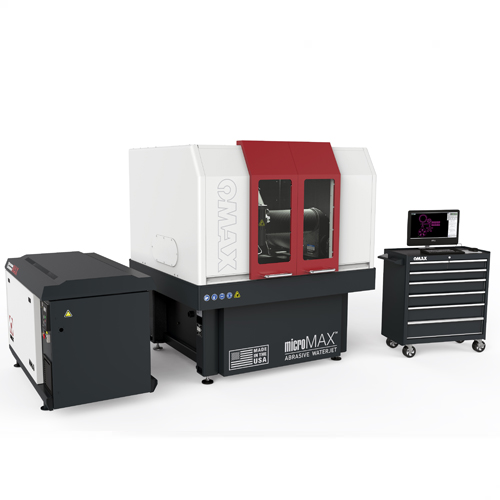

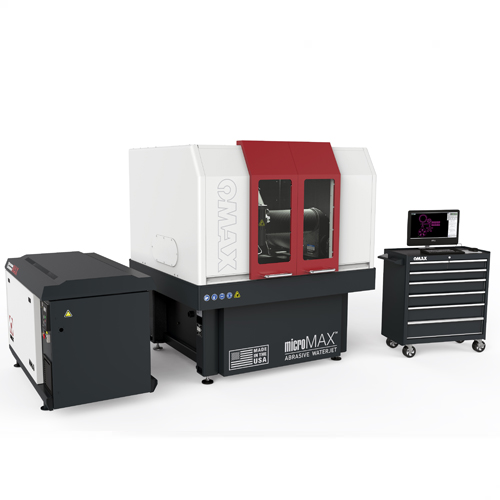

OMAX MicroMAX

The MicroMAX is the industry’s most precise abrasive waterjet with a positioning accuracy of less than five microns. The machine is capable of cutting extremely small parts in virtually any material. The advanced Tilt-A-Jet cutting head on the machine allows for taper-free edges and rapid cutting speeds.

The MicroMAX JetMachining Centre is the ideal solution for ultra-precision abrasive waterjet machining. Utilising advanced high-precision optical linear encoders, innovative vibration isolation, and proven software control systems, the MicroMAX JetMachining Centre is capable of a positioning accuracy of less than five microns while retaining all the advantages of abrasive waterjet machining. The MicroMAX can machine stainless steel, titanium, carbon fibre, PEEK, glass, nitinol, graphite, copper, composites, laminates, and more, with high precision and smooth finishing, for either prototyping or production.

Ideal for production runs and prototype development, the MicroMAX is a highly rigid machine with a table size of 2 feet 4 inches by 2 feet 4 inches and an X-Y cutting travel of 2 feet by 2 feet.

For further information and orders, please contact 01257 248480.

Description

Like all OMAX JetMachining Centres, the MicroMAX is a flexible, cost-effective and beneficial alternative to conventional machining operations. Because waterjet-based machining is a cold-cutting process, it eliminates thermal stress in the workpiece, preventing hardening and warping. The MicroMAX also enables manufacturers across all industry segments to accomplish quick turnaround of accurate parts without the hassle of tool changes or complex fixturing, as well as achieve smooth surface finishes without the need for secondary machining.

Machine Dimensions

| Footprint * – (L x W) | 1,880 mm x 2,134 mm |

| Height ** | 2,134 mm |

| Weight (tank empty) | 1,724 kg |

Work Envelope

| X-Y Cutting Envelope *** | 635 mm x 635 mm |

| Z-Axis Travel *** | 114 mm |

| Table Size – (L x W) | 889 mm x 914 mm |

Standard Model Specifications

| Speed | 2,540 mm/min |

| Repeatability | ±0.0025 mm |

| Ballbar Circularity | ±0.0152 µm |

* Footprint does not include controller or pump.

** With standard scissor plumbing.

*** Additional accessories may reduce travel.

Features & Benefits

- Small, efficient footprint for minimal floorspace utilization

- Very high precision with 0.1 micron linear optical encoder system

- Highly rigid structure with low mass bridges and carriages

- Stiff construction greatly reduces vibration and increases accuracy

- Vibration isolation of table and gantries

- All components have matched thermal expansion

- Revolutionary patent-pending process for fine abrasive feed rate

- Full enclosure with environmental controls provides quiet, safe and clean operation below 80db

- Advanced pressure controls for piercing delicate materials

- No heat-affected zones or mechanical stresses

- Standard OMAX 7/15 Mini MAXJET 5 Nozzle acquires finer precision cutting capability with a 0.007″ orifice and a 0.015″ mixing tube combination

- Standard Tilt-A-Jet taper eliminating abrasivejet cutting head

- Standard Rapid Water Level Control for cleaner, safer, and quieter submerged cutting completes most work below 80 dBA

- Machines a wide range of materials with high accuracy

- Can machine hardened steel as easily as annealed steel

- Easily cut non-conductive and reflective materials

- Leaves behind a satin-smooth edge, reducing secondary operations

- Shipped as a completely pre-assembled and factory-tested system

- Designed and manufactured at the OMAX factory in Kent, Washington, USA

Other OMAX Machines

OMAX MicroMAX

OMAX 80X Series

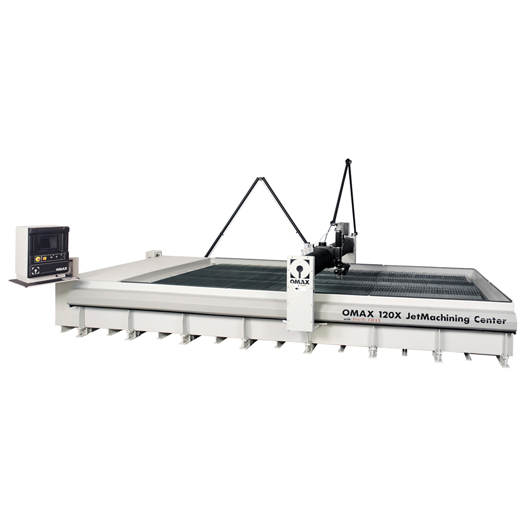

OMAX 120X Series

OMAX 160X Series

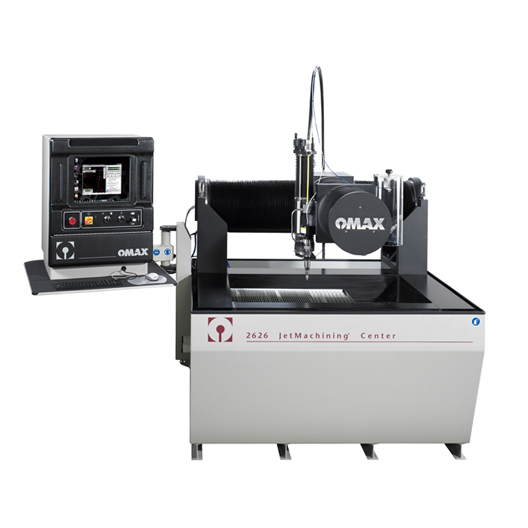

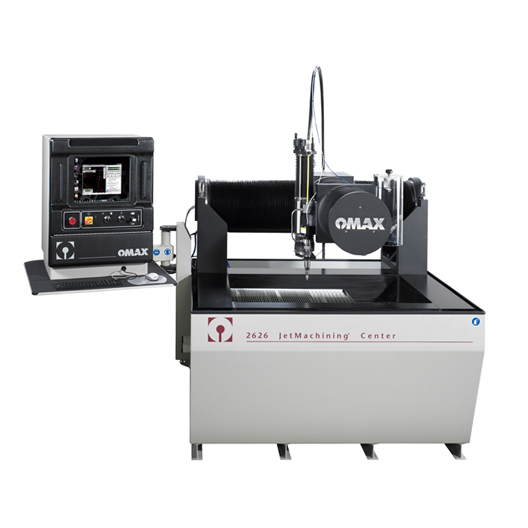

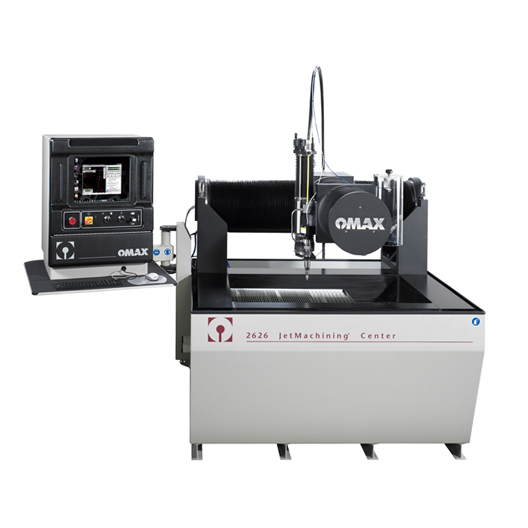

OMAX 2626

OMAX 2652

OMAX 5555

OMAX 55100

OMAX 60120 Series

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)

OMAX MicroMAX

The MicroMAX is the industry’s most precise abrasive waterjet with a positioning accuracy of less than five microns. The machine is capable of cutting extremely small parts in virtually any material. The advanced Tilt-A-Jet cutting head on the machine allows for taper-free edges and rapid cutting speeds.

The MicroMAX JetMachining Centre is the ideal solution for ultra-precision abrasive waterjet machining. Utilising advanced high-precision optical linear encoders, innovative vibration isolation, and proven software control systems, the MicroMAX JetMachining Centre is capable of a positioning accuracy of less than five microns while retaining all the advantages of abrasive waterjet machining. The MicroMAX can machine stainless steel, titanium, carbon fibre, PEEK, glass, nitinol, graphite, copper, composites, laminates, and more, with high precision and smooth finishing, for either prototyping or production.

Ideal for production runs and prototype development, the MicroMAX is a highly rigid machine with a table size of 2 feet 4 inches by 2 feet 4 inches and an X-Y cutting travel of 2 feet by 2 feet.

For further information and orders, please contact 01257 248480.

Description

Like all OMAX JetMachining Centres, the MicroMAX is a flexible, cost-effective and beneficial alternative to conventional machining operations. Because waterjet-based machining is a cold-cutting process, it eliminates thermal stress in the workpiece, preventing hardening and warping. The MicroMAX also enables manufacturers across all industry segments to accomplish quick turnaround of accurate parts without the hassle of tool changes or complex fixturing, as well as achieve smooth surface finishes without the need for secondary machining.

Machine Dimensions

| Footprint * – (L x W) | 1,880 mm x 2,134 mm |

| Height ** | 2,134 mm |

| Weight (tank empty) | 1,724 kg |

Work Envelope

| X-Y Cutting Envelope *** | 635 mm x 635 mm |

| Z-Axis Travel *** | 114 mm |

| Table Size – (L x W) | 889 mm x 914 mm |

Standard Model Specifications

| Speed | 2,540 mm/min |

| Repeatability | ±0.0025 mm |

| Ballbar Circularity | ±0.0152 µm |

* Footprint does not include controller or pump.

** With standard scissor plumbing.

*** Additional accessories may reduce travel.

Features & Benefits

- Small, efficient footprint for minimal floorspace utilization

- Very high precision with 0.1 micron linear optical encoder system

- Highly rigid structure with low mass bridges and carriages

- Stiff construction greatly reduces vibration and increases accuracy

- Vibration isolation of table and gantries

- All components have matched thermal expansion

- Revolutionary patent-pending process for fine abrasive feed rate

- Full enclosure with environmental controls provides quiet, safe and clean operation below 80db

- Advanced pressure controls for piercing delicate materials

- No heat-affected zones or mechanical stresses

- Standard OMAX 7/15 Mini MAXJET 5 Nozzle acquires finer precision cutting capability with a 0.007″ orifice and a 0.015″ mixing tube combination

- Standard Tilt-A-Jet taper eliminating abrasivejet cutting head

- Standard Rapid Water Level Control for cleaner, safer, and quieter submerged cutting completes most work below 80 dBA

- Machines a wide range of materials with high accuracy

- Can machine hardened steel as easily as annealed steel

- Easily cut non-conductive and reflective materials

- Leaves behind a satin-smooth edge, reducing secondary operations

- Shipped as a completely pre-assembled and factory-tested system

- Designed and manufactured at the OMAX factory in Kent, Washington, USA

Other OMAX Machines

OMAX MicroMAX

OMAX 80X Series

OMAX 120X Series

OMAX 160X Series

OMAX 2626

OMAX 2652

OMAX 5555

OMAX 55100

OMAX 60120 Series

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)

OMAX MicroMAX

The MicroMAX is the industry’s most precise abrasive waterjet with a positioning accuracy of less than five microns. The machine is capable of cutting extremely small parts in virtually any material. The advanced Tilt-A-Jet cutting head on the machine allows for taper-free edges and rapid cutting speeds.

The MicroMAX JetMachining Centre is the ideal solution for ultra-precision abrasive waterjet machining. Utilising advanced high-precision optical linear encoders, innovative vibration isolation, and proven software control systems, the MicroMAX JetMachining Centre is capable of a positioning accuracy of less than five microns while retaining all the advantages of abrasive waterjet machining. The MicroMAX can machine stainless steel, titanium, carbon fibre, PEEK, glass, nitinol, graphite, copper, composites, laminates, and more, with high precision and smooth finishing, for either prototyping or production.

Ideal for production runs and prototype development, the MicroMAX is a highly rigid machine with a table size of 2 feet 4 inches by 2 feet 4 inches and an X-Y cutting travel of 2 feet by 2 feet.

For further information and orders, please contact 01257 248480.

Description

Like all OMAX JetMachining Centres, the MicroMAX is a flexible, cost-effective and beneficial alternative to conventional machining operations. Because waterjet-based machining is a cold-cutting process, it eliminates thermal stress in the workpiece, preventing hardening and warping. The MicroMAX also enables manufacturers across all industry segments to accomplish quick turnaround of accurate parts without the hassle of tool changes or complex fixturing, as well as achieve smooth surface finishes without the need for secondary machining.

Machine Dimensions

| Footprint * – (L x W) | 1,880 mm x 2,134 mm |

| Height ** | 2,134 mm |

| Weight (tank empty) | 1,724 kg |

Work Envelope

| X-Y Cutting Envelope *** | 635 mm x 635 mm |

| Z-Axis Travel *** | 114 mm |

| Table Size – (L x W) | 889 mm x 914 mm |

Standard Model Specifications

| Speed | 2,540 mm/min |

| Repeatability | ±0.0025 mm |

| Ballbar Circularity | ±0.0152 µm |

* Footprint does not include controller or pump.

** With standard scissor plumbing.

*** Additional accessories may reduce travel.

Features & Benefits

- Small, efficient footprint for minimal floorspace utilization

- Very high precision with 0.1 micron linear optical encoder system

- Highly rigid structure with low mass bridges and carriages

- Stiff construction greatly reduces vibration and increases accuracy

- Vibration isolation of table and gantries

- All components have matched thermal expansion

- Revolutionary patent-pending process for fine abrasive feed rate

- Full enclosure with environmental controls provides quiet, safe and clean operation below 80db

- Advanced pressure controls for piercing delicate materials

- No heat-affected zones or mechanical stresses

- Standard OMAX 7/15 Mini MAXJET 5 Nozzle acquires finer precision cutting capability with a 0.007″ orifice and a 0.015″ mixing tube combination

- Standard Tilt-A-Jet taper eliminating abrasivejet cutting head

- Standard Rapid Water Level Control for cleaner, safer, and quieter submerged cutting completes most work below 80 dBA

- Machines a wide range of materials with high accuracy

- Can machine hardened steel as easily as annealed steel

- Easily cut non-conductive and reflective materials

- Leaves behind a satin-smooth edge, reducing secondary operations

- Shipped as a completely pre-assembled and factory-tested system

- Designed and manufactured at the OMAX factory in Kent, Washington, USA

Other OMAX Machines

OMAX MicroMAX

OMAX 80X Series

OMAX 120X Series

OMAX 160X Series

OMAX 2626

OMAX 2652

OMAX 5555

OMAX 55100

OMAX 60120 Series

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)